What are the 3 types of centrifugal pumps? Single-stage, Two-stage, or Multi-stage.

What are the disadvantages of centrifugal pump? The main disadvantage is that they use rotation instead of suction to move water, and therefore have almost no suction power. This means that a centrifugal pump must be put under water, or primed, before it will move water. Centrifugal pumps can also develop a phenomenon called “cavitation”.

What is a centrifugal pump used for? Centrifugal pumps are commonly used for pumping water, solvents, organics, oils, acids, bases and any ‘thin’ liquids in both industrial, agricultural and domestic applications. In fact, there is a design of centrifugal pump suitable for virtually any application involving low viscosity fluids.

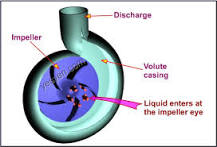

What is the working principle of centrifugal pump? The basic principle of operation of centrifugal pumps is – force vortex flow. This means, when a body of liquid is acted upon by an external torque, it increases the pressure head of the rotating liquid. This increase in pressure is directly proportional to the velocity of the liquid.

How long can a centrifugal pump run continuously? A continuous-duty motor can function non-stop for up to 24 hours under high demand to move water out of your home, but the motor does not last as long as an intermittent-style sump pump motor.

How do you calculate pump RPM? – Related Questions

What is the flow of centrifugal pump?

Centrifugal pumps generate flow by using one of three actions: radial flow, mixed flow, or axial flow. Axial flow pumps are characterized by high flow and low pressure.

What is specific speed of centrifugal pump?

Concept: The specific speed of a centrifugal pump is defined as the speed of a geometrically similar pump which would deliver one cubic metre of liquid per second against a head of one metre. N s = N Q H m 3 / 4.

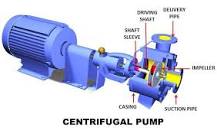

What are the main components of a centrifugal pump?

- Impeller. An impeller is a rotor used to increase the kinetic energy of the flow.

- Casing (Volute). The casing contains the liquid and acts as a pressure containment vessel that directs the liquid flow in and out of the centrifugal pump. …

- Shaft (Rotor). …

- Shaft sealing. …

- Bearings.

What are the difference between centrifugal pump and reciprocating pump?

The reciprocating pump provides a nearly constant flow rate over a wider range of pressure; the centrifugal pump gives uniform pressure over a range of flow, then it drops dramatically as the flow rate increases. On a reciprocating pump, fluid viscosity has little effect on the flow rate as the pressure increases.

Why it is called centrifugal pump?

A centrifugal pump uses a centrifugal force to pump the fluids. Therefore, it is known as a centrifugal pump. It is a simplest type of hydraulic equipment that uses in a wide variety of industries and in many everyday appliances to move fluids from low to high-pressure areas.

Which motor is used in centrifugal pump?

DC shunt motor: It is an almost constant speed motor. Hence it is used for driving constant speed line shafts, lathes, centrifugal pumps, small printing presses, paper making machines, etc.

Can a centrifugal pump over pressure?

When a centrifugal pump is dead-heading, it can lead to explosions, due to the energy being put into the liquid in the pump. Hydraulic overpressure and possible chemical reactions in the pump can also be caused by the overexertion of pressure.

What are the main advantages of centrifugal pump?

- Corrosion Resistance. Finish Thompson’s centrifugal chemical pumps are manufactured using corrosion-resistant materials. …

- Energy Efficiency. …

- Smooth Flow. …

- Proven Reliability. …

- Low Maintenance. …

- Size Versatility. …

- Application Versatility.

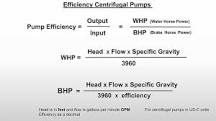

What is efficiency of centrifugal pump?

Centrifugal pumps can approach 94 percent efficiency, but typical efficiencies are 55 percent for small pumps and 70 percent for large pumps. The amount of electrical energy used by the pumps in an average industrial facility will vary by plant type.

What are the types of centrifugal pump?

Accordingly, radial, Axial, and Mixed flow are three types of centrifugal pumps.

What happens if a centrifugal pump runs dry?

In the absence of liquid, dry running can occur in certain areas because of insufficient cooling and centring action. The consequences are overheating, abrasion, seizure of the materials, vibrations and other phenomena which may in due course lead to the complete disintegration of the pump.

Can water flow through a centrifugal pump that is off?

Many pumps, when turned off, will still pass water. If there’s any pressure at all upstream of the pump, the impeller will turn and water will leak through in the forward direction. To prevent backflow of course, a check valve is used.

What is suction pressure of centrifugal pump?

| CENTRIFUGAL PUMP SIZING | |

|---|---|

| FLUID NAME: | GAS-OIL |

| TOTAL PUMP SUCTION PRESSURE, psig: | 18.183 |

| TOTAL PUMP SUCTION PRESSURE, psia: | 32.883 |

| AVAILABLE NET POSITIVE SUCTION HEAD, ft.: | 64.153 |

What are the 2 types of pumps?

Main Types of Pumps: Centrifugal and Positive Displacement.

What is the capacity of centrifugal pump?

A centrifugal pump with a capacity of 100–200 gallons per minute (gpm) with proper NPSH calculated on the basis of water temperature of 200°F (93.3°C) is used for pumping water through the system.

What is the formula of centrifugal pump?

The centrifugal pump discharge formula is Q = π. B1 and B2 = Width of the impeller at inlet and outlet. Vf1 and Vf2 = Flow velocity and inlet and outlet.

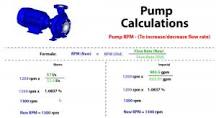

What is pump RPM?

Pump RPM is the rotational speed of a pump. It is measured in revolutions per minute or RPM. RPM is important because it affects the efficiency of the pump and how quickly water is moved through the system. Increasing pump RPM can increase water flow and decrease pumping time.

What is minimum starting speed of centrifugal pump?

To get the minimum starting speed of a centrifugal pump, it is notice that if the pressure rise in the Impeller is more than or equal to manometric head (Hm) then the centrifugal pump will start to deliver water. Otherwise the pump will not discharge any water, the impeller is rotating.

What are the advantages and disadvantage of centrifugal pump?

- Small in size, space saving & less capital costs.

- Easy for maintenance.

- No danger creates if discharge v/v is closed while starting.

- Deal with large volume.

- Able to work medium to low head.

- Able to work medium to low viscous fluid.

Which bearing is used in centrifugal pump?

The three most used ball bearing types are the single row deep groove ball bearing, double row angular contact ball bearing and universally matchable single row angular contact ball bearing. Ball bearings are most commonly used in small and medium sized pumps because of their high speed capability and low friction.

What is pump and working principle?

A Pump is generally used to induce flow or raise the pressure of a liquid. Centrifugal pumps are a category of Dynamic pumps. The working principle of centrifugal pumps involves imparting energy to the liquid by means of a centrifugal force developed by the rotation of an impeller that has several blades or vanes.

Which pump is best centrifugal or reciprocating?

In general, a reciprocating pump is more efficient than a centrifugal pump. Reciprocating machines are generally applied on low-flow/high-head service. Centrifugal pumps can have efficiencies as low as 40 percent on low-flow/high-head service.

Why reciprocating pump is more efficient than centrifugal pump?

Advantages of Reciprocating Pumps Over Centrifugal Pumps The flow rate of a centrifugal pump may fluctuate during operation while a reciprocating pump provides a steady, unchanging flow rate. Reciprocating pumps are ideal for high-pressure, low-flow applications.

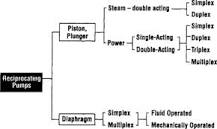

Why we use reciprocating pump?

Reciprocating pumps are used where a precise amount of fluid is required to be delivered, also where the delivery pressure required is higher than can be achieved with other types. The fluid is moved by the means of a piston that travels in a cylinder.

What are the 3 types of impellers?

- Open impeller. Open impellers have the vanes free on both sides. …

- Semi-open impeller. The vanes are free on one side and enclosed on the other. …

- Closed impeller. The vanes are located between the two discs, all in a single casting.

What are the 2 types of pumps?

Main Types of Pumps: Centrifugal and Positive Displacement.

What are the two main classes of centrifugal pumps?

Pumps are divided into 2 major categories: Dynamic and Positive Displacement (aka Displacement).

What are main types of pumps?

There are three basic types of pumps: positive-displacement, centrifugal and axial-flow pumps.