How do I fix my garden hose spray nozzle?

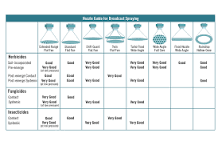

Which nozzle is best for herbicide spray? Because of their ability to produce a very uniform pattern when correctly overlapped, the flat-fan nozzle type is generally the best choice for the broadcast application of herbicides.

Why does my garden nozzle leak? A bent coupling loses the watertight seal between the hose and a spigot, nozzle, or sprinkler, causing a leak. Replacing a bent coupling with a new one that suits your needs will provide a permanent solution for the leak.

Are there different size hose nozzles? Garden hose connectors usually come in 3/4 or 5/8-inch. It is according to the inside diameter of the hose. Garden hose fittings also vary accordingly and the most popular size is 3/4-inch or 11.5NH. This size is also perfect for commercial purposes.

How do I fix a leaky spray nozzle?

How do you fix a clogged garden sprayer? – Related Questions

How do you clean a clogged hose nozzle?

Fill the bucket with an equal solution of vinegar and hot water. Heat the water for five to 10 minutes on the stove. Ensure the water is not boiling. Unscrew the nozzles from the water hose.

Which nozzle is most commonly used for herbicide application?

Flat-fan nozzles are widely used for broadcast spraying of herbicides. These nozzles produce a tapered-edge, flat-fan spray pattern (Figure 2A).

How do I choose a nozzle size?

The correct nozzle height is measured from the nozzle to the target, which may be the top of the ground, growing canopy, or stubble. Use 110-degree nozzles when booms are less than 30 inches high with 30-inch nozzle spacing; use 80-degree nozzles when the booms are higher.

What are the three types of nozzles?

- Nozzle.

- The Nozzle Tip is one of the most important and least expensive part of a spraying system. Adjustable nozzle.

- Double swirl spray nozzle.

- Selecting a spray nozzle.

- Hollow cone nozzles-Disc and core type.

- Flat fan nozzles.

- Floodjet nozzles.

- Adjustable nozzles.

Why does my faucet leak when I attach a hose?

Worn Gasket The coupling is composed of the gasket—a thin ring made of rubber or silicone—and the spigot itself (also known as a hose bib or faucet). The gasket can wear down over time, meaning it isn’t watertight and may cause a leak. In this case, replacing the gasket will fix the issue.

What is the most common garden hose size?

Hose Diameter – Width = Water Flow The most common garden hose diameters are ¾ inch, five-eighths inch and half inch. These measurements are based on the inside diameter of the hose, not the outside. The bigger the diameter, the more water the hose will carry. A hose width of five-eighths inch is generally most useful.

How can I tell what size my garden hose is?

Inner Diameter Most hoses used in North America are designated in inches of ID. For industrial hoses, it is most common to see the size in direct terms of the inch size. For example, a 3/4” measured hose ID will be designated as either a “3/4” or in terms of decimal size “. 75”.

What is the difference between 3/4 and 5/8 garden hose?

As you water your yard, the stream does not rush out in wide torrents using the 5/8-inch hose, which might cause puddling and flooding. In contrast, the wider 3/4-inch hose provides more water volume each minute because the flow has a larger pathway.

Why is my sprayer not building pressure?

If you are experiencing low pressure output from your sprayer and have ruled out any other parts as the cause, the impeller coupling may have lost its seal, or the impeller itself may be damaged, clogged or broken. In some cases, the pump may be disassembled and cleaned to fix the problem.

Why is my pump sprayer not spraying?

What are the 2 types of nozzles?

The two most popular types for chemical applica- tions are the flat spray and hollow cone nozzles.

What do the numbers on spray nozzles mean?

Most companies identify their flat-fan nozzles with a four or five digit number (Figure 2). The first numbers are the spray angle and the other numbers signify the discharge rate at rated pressure. For example, an 8005 has an 80 degree spray angle and will apply 0.5 gallons per minute (GPM) at rated pressure of 40 psi.

What are the different types of spray nozzles?

There are 5 basic spray pattern types: flat fan, solid stream, full cone, hollow cone and mist/fog.

How do I choose a nozzle?

Selecting Your Nozzle Size You’ll want to determine the nozzle flow rate at gallons per minute (gpm). To find that, start with your application rate in gallons per acre (gpa). Next, find an efficient and safe ground speed in miles per hour (mph). Then, determine the spray width per nozzle (W).

Can you print 0.2 mm with a 0.4 mm nozzle?

So for a 0.4mm nozzle, you’ll be looking to print at 0.2mm layer height, or up to 0.3mm. Your minimum would want to be around 0.1mm, any lower than this and you’re just increasing your waiting time for not much benefit (on the same 0.4mm size nozzle).

Are DiamondBack nozzles worth it?

The DiamondBack Nozzle delivers precision prints, prints any filament, and offers a much longer nozzle life. In addition, the DiamondBack is easier to clean, reduces tip clogging, improves layer adhesion, lowers operating temperature, and delivers unmatched wear resistance.

Do nozzles increase pressure?

In a convergent nozzle, there is an increase in velocity and a decrease in pressure, but we know that pressure is inversely proportional to area.

What are flat fan nozzles used for?

Flat-fan (A): These are the most common nozzles used for turf applications and produce a fine to medium droplet. Spray coverage is excellent but drift may be a concern. Air-induction (B): These nozzles produce a medium to coarse droplet which shatters upon contact with the leaf blade to provide better coverage.

What is a cone nozzle used for?

Solid cone nozzles are suitable for application of residual herbicides and systemic insecticides using a knapsack or boom mounted or for spot applications of herbicides. They produce a full cone spray pattern with coarse droplets at a pressure of 1 – 10 bar.

How do you fix a nozzle on a brass hose?

How does a garden hose nozzle work?

Most hose nozzles allow you to shut off the flow of water by moving a valve, twisting or rotating the barrel, or releasing the trigger. This is often a point of failure; look for a valve that’s well-made, strongly attached, and fully stops the flow of water when in the “Off” position.