The pump operates by receiving a fluid through the inlet port where it is captured and transported by the rollers, and then expelled through the outlet port. Construction features include housings and rollers, which are made in a variety of materials in order to be resistant to a wide range of chemicals.

How do you make a sprayer boom?

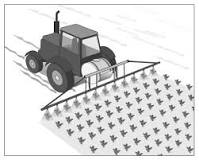

What is the difference between boom and Boomless sprayer? A boomless sprayer generally has one or two nozzles that can be pointed out sideways or tilted slightly up and spray out further achieve coverage. A boom sprayer typically has multiple spray tips spread out along both boom arms with even spacing and are pointed straight down towards the target.

What are spray booms? : a pipe with attached nozzles for distributing spray from a tank.

How high should sprayer booms be? This is an 80 degree angle nozzle designed to operate at 30 inches above the target for the recommended 100 percent overlap coverage. In this case, the target was weeds, so the boom needed to be 30 inches above the average weed height. Spraying 30 inches above the target will subject the spray to more drift.

How do you make a tank sprayer?

How does a roller pump work? – Related Questions

How do you make a ATV sprayer?

Why is it called a boom sprayer?

What is Boom Spraying? A Boom Sprayer usually has multiple spray nozzles (tips are usually the American terminology) spread out along arms (booms), pointed directly down.

What are the disadvantages of sprayer?

Disadvantages :1. Low efficiency and large labor intensity are not suitable for large-scale operation. 2. The liquid has run, run, run, leak and drip phenomenon.

What does Boomless mean?

: being without a boom.

How many nozzles does a boom sprayer have?

Five nozzles can produce the required flow, each at different pressures.

What are the types of sprayer?

- Boom sprayer.

- Boomless sprayer nozzle.

- Mist sprayer.

- Three-point hitch sprayer.

- Truck-bed sprayer.

- Towing-hitch sprayer.

- UTV sprayer.

- ATV sprayer.

How far apart should spray nozzles be?

Nozzle Spacing The most common nozzle spacings are 20 and 30 inches. Many sprayers are now being converted from 30 inch to 15 inch spacings. The 30-inch spacing is used for the lower application rates (7 to 10 gallons per acre) and the 15-inch spacing for the higher application rates (14 gallons per acre and higher).

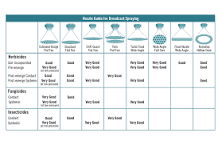

Which nozzle is best for herbicide spray?

Because of their ability to produce a very uniform pattern when correctly overlapped, the flat-fan nozzle type is generally the best choice for the broadcast application of herbicides.

How do you choose nozzles?

Selecting Your Nozzle Size You’ll want to determine the nozzle flow rate at gallons per minute (gpm). To find that, start with your application rate in gallons per acre (gpa). Next, find an efficient and safe ground speed in miles per hour (mph). Then, determine the spray width per nozzle (W).

Which type of nozzle should be used for the spraying of pesticides?

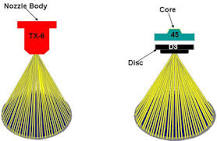

Fan Nozzles The most common type of nozzle used in agriculture is the fan nozzle. A fan nozzle is widely used for spraying pesticides — both banding (over and between rows) and broadcast applications. These nozzles produce a tapered-edge, flat-fan spray pattern (Figure 2).

How do you calibrate a sprayer boom?

- Select a travel distance from Table 1 based on row spacing. …

- Drive 136 feet and measure the time in seconds.

- If it took 15 seconds, catch the output from each of the three nozzles for 15 seconds. …

- Repeat Step 3 for each set of nozzles on the boom to make sure the application rate is uniform across the boom.

How do you make an electric garden sprayer?

How do you make homemade foam markers?

How do you mount a ATV sprayer?

How do you attach a Boomless spray nozzle?

Why do farmers use sprayers?

While sprayers were once a niche product, today sprayers have become an essential piece of farm equipment for effective crop production. By properly applying chemicals to control weeds, insects, and diseases, you give your crop the best chance for high yields.

What are the components of a boom sprayer?

- Hose Drops & Hose Swivels. 19 items.

- Nozzle Bodies. 300 items.

- Nozzle Body Boom Clamps. 23 items.

- Tip Screens & Tip Check Valves. 55 items.

Which of the sprayer is mostly used by farmer?

Tractor-mounted sprayers are the most used, easy controls and well-engineered nozzles arrangements that carry out accurate Spraying of chemicals on the crops.

What is the advantage of using power sprayer?

Electric power sprayers have fewer moving parts and often have simpler plumbing. This means less can go wrong, fewer parts to maintain in inventory, and easier maintenance. Greener image. Electric battery-powered sprayer motors give operators a greener image.

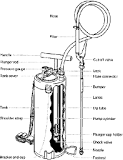

What is the category of knapsack sprayer?

There are three types of Knapsack sprayers i.e battery, manual and battery cum manual sprayer. Portable power sprayers are operated by electric and petrol engine with the help of hose pipe.

What is the function of hose in knapsack sprayer?

The pump, mounted on a footrest or stirrup, is inserted in the spray liquid in a bucket. A hose attached to the pump leads to the spray lance. Two persons are needed, one to pump and one to direct the spray. The pressure varies with the speed of pumping, and so it is difficult to make uniform spray applications.

What is a Boomless spray nozzle?

Boomless nozzles are used for spraying areas not easily accessed with a boom. Choose from single brass, stainless steel, nylon nozzles or the double-sided BoomJet suited for large capacity 12 volt or medium pressure diaphragm pumps. Boomless nozzles can spray widths from 3 to 19 metres.

What is a Boomless nozzle?

Boomless nozzles are used for vegetative management activities where it’s not practical, or sometimes even impossible, to use a horizontal boom. Consider highway easements and ditches, railways, and infrastructure like buildings, powerline poles or fence posts.

What is boom headset?

A microphone boom headset includes a microphone mounted on a boom that is attached to the ear cup or band of the headset. The boom is flexible and can be… moved in any direction, allowing the user to talk into the microphone while keeping both hands free.

How do you make homemade foam markers?

How do you make an electric sprayer?

How do you make a paint sprayer?

How do you make a spray bottle out of a plastic bottle?

Make sure the spray cap is unscrewed from the bottle. Then, slice the plastic in a circle about 2 cm (0.79 in) away from the mouth to remove it from the bottle. You don’t have to cut around the mouth in a perfect circle — just try to make the width roughly the same all the way around.