Because diaphragm pumps are so versatile, they are used in virtually every industry that requires fluid transfer. They are often used for dewatering or water removal across many different industries. They are used for filling, dispensing and metering due to their efficiency and accuracy.

What is a diaphragm spray pump? Diaphragm Sprayers: Diaphragm pumps feature a flat, diaphragm inside of a housing held together by screws. When pumping, the diaphragm flexes up and down to create pressure. These pumps tend to be more durable because there is no contact with the cylinder wall. Diaphragm pumps can reach up to 60 psi.

Is diaphragm or piston sprayer better? Piston – A piston pump is the better option when spraying anything at a distance, such as trees and bushes, because of its higher pressure. They are normally a little less expensive and easier to repair. However, they aren’t as durable as a diaphragm pump.

What are the disadvantages of a diaphragm pump?

| Advantages | Disadvantages |

|---|---|

| Seal-less and oil-free | Low maximum speed |

| Self-priming up to 6 meters | Not very energy efficient |

| Simple cleaning/maintenance | Pulsed flow – requires dampener for reduction |

| Versatile design and function (can handle most media types) |

How does a diaphragm airless paint sprayer work? Diaphragm pumps In a diaphragm pump, a rod powered by a motor operates diaphragms that expand and contract, taking in fluid through the inlet valve and expelling it out of the gun.

What are diaphragm pumps used for? – Related Questions

How does a piston diaphragm pump work?

Each piston is located in a separate oil chamber that equalizes the pressure of the oil behind the diaphragm to the media-side pressure. During the discharge stroke of the piston, the oil is compressed, causing the respective membrane to move outward and push the liquid out of the pump head.

Does diaphragm pump need electricity?

The pumps are self-priming so they can run dry without any damage and because they are powered entirely from compressed air, there is no need for electricity.

Can a diaphragm pump run dry?

Double Diaphragm Pumps Can Run Dry Without Damaging the Pump or System. AODD pumps can run dry for an extended period of time without damaging the pump or its components. It’s very common for pumps to run dry.

How far can a diaphragm pump work?

The Diaphragms operate the internal valves on the side of the pump which help to control flow direction and fluid quantity being transferred to the discharge outlet. Tapflo’s Diaphragm Pumps are able to self-prime up to 5m from a dry suction pipe or 8m from a wetted pipe.

What is a linear diaphragm pump?

Linear diaphragm pumps are equipped with linear magnetic and vibrating armature motor types. Linear pumps use electromagnetic force to move the piston or diaphragm up and down, and pump the air or liquid.

How do you pump a backpack sprayer?

How does back pack sprayer work?

Most backpack sprayers feature a pressure vessel. This provides constant pressure, ensuring the liquid is sprayed evenly. Some backpack sprayers are equipped with a pressure gauge on the valve, which indicates the spray pressure. A constant pressure is important for a uniform spray pattern.

How long do diaphragm pumps last?

In general, diaphragms on metering pumps last about 6 to 12 months; gears on gear pumps last about 3 to 6 months; and motors usually last for years.

How high can a diaphragm pump lift water?

A safe, average range would be between 8 to 15 feet (2.44 to 4.57 meters) depending on the pump’s elastomers.

What is the major advantage of a diaphragm pump over a centrifugal pump?

3 BIG ADVANTAGES OF USING DIAPHRAGM AGRICULTURAL PUMPS The 3 main advantages of a diaphragm pump compared to a centrifugal pump are: Excellent head and self-priming capacity. Good dry running capacity. Resistance to abrasion and corrosion.

What PSI should latex paint be?

For spraying latex paint, there are two pressures to keep in mind, depending on what you are painting: A 26 – 29 PSI is suggested for a base coat on the surface being painted; A clear coat is better served by a lower 2 – 3 PSI for better atomization (remember that from earlier?) and flow.

What pressure should I set my airless sprayer?

1500 – 3000 psi) and is partially atomized through a small tip. Full atomization is achieved by adding a small amount of air (5 – 35 psi) to the edges of the spray fan – resulting in a softer pattern, more control, higher transfer efficiency, and less overspray.

Can you spray oil based paint with an airless sprayer?

Airless pain sprayers work with oil-based paint or stain. HVLP paint sprayers work with oil-based paint, but thicker paints such as water-based latex can clog the sprayer.

How much suction does a diaphragm pump have?

Normally, the suction lift of a diaphragm pump is limited to that corresponding to 14 feet of water at sea level. This amounts to a lift of approximately eight feet when pumping pulp containing 50% solids when the specific gravity of the dry solids is 2.65.

Can diaphragm pumps pump air?

Air-operated diaphragm pumps are positive displacement pumps that transfer liquids in wet commercial pumping applications. They run on compressed air and move slurries, solvents, and other high-viscosity liquids.

What is the difference between a centrifugal and a diaphragm style pump?

Centrifugal pumps are simple compared to diaphragm pumps. With so few moving parts, a centrifugal pump needs less maintenance and can last longer than a diaphragm pump. A centrifugal pump has no gearbox, diaphragms, check valves, sight glass, pulsation damper, gear lube, or crankcase oil.

Does Aodd pump require electricity?

AODD pumps require no electricity (rather, they require compressed air to operate) and can be grounded for safe, reliable operation in explosive environments. This is critical when pumping flammable liquids or when a pump is in an environment where fumes are present.

What causes diaphragm pump failure?

The liquid is leaking from your pump Diaphragm rupture: Causes of a failed or ruptured diaphragm include overuse, abrasion, chemical attack or overpressure to name a few. A rupture means fluid will leak into the air valve and leak through the pump’s muffler.

Does a diaphragm pump need to be primed?

Air operated diaphragm pumps self-prime by creating a pressure differential in the diaphragm chamber – which draws in air and pulls the fluid into the suction port. Avoid failures and maintenance costs by ensuring your centrifugal pumps are always primed before operating.

Can a diaphragm pump Cavitate?

Cavitation can occur in the suction valve of a diaphragm pump if the valve is designed improperly or the inlet pressure is not high enough during operation of the pump. 1D analysis of suction valve motion may be helpful to identify cavitation issue during operation of a diaphragm pump.

Can a diaphragm pump pull a vacuum?

Modern multi-stage diaphragm pumps can provide vacuum levels throughout the entire rough vacuum range (atmosphere to below 1 mbar/torr) providing vacuum levels suitable for many tasks. Standard models can perform degassing of liquids, and even be used as backing pumps for wide range turbomolecular pumps.

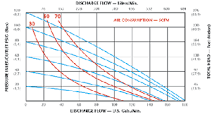

How do you size a diaphragm pump?

So, the rule of thumb is as follows: take the liquid flow rate of the pump you’re considering and multiply that number by 0.75. That’s the CFM you’ll need for most cases. For example, if you’re looking at the SimpleSpirits 43, its liquid flow rate is 49 GPM.

Are diaphragm pumps loud?

Diaphragm pumps are also quiet because valves are usually made of rubber. However, to achieve high pressure that compares with plunger pumps, valves need to be manufactured out of rigid materials like stainless steel which produce a mechanical noise.

Can I use a diaphragm pump to pump water?

What is the difference between a centrifugal and a diaphragm style pump?

Centrifugal pumps are simple compared to diaphragm pumps. With so few moving parts, a centrifugal pump needs less maintenance and can last longer than a diaphragm pump. A centrifugal pump has no gearbox, diaphragms, check valves, sight glass, pulsation damper, gear lube, or crankcase oil.

Can you flow through a diaphragm pump?

WHAT KIND OF FLUID DOES A DIAPHRAGM PUMP TRANSFER? Diaphragm pumps will move nearly any kind of fluid. Some common examples of fluids pumped using a diaphragm pump are water, oil and acid. Diaphragm pumps are capable of pumping high viscosity fluids from adhesives and gear oils to hand lotions, surfactants and resins.

Will a diaphragm pump pull a vacuum?

Modern multi-stage diaphragm pumps can provide vacuum levels throughout the entire rough vacuum range (atmosphere to below 1 mbar/torr) providing vacuum levels suitable for many tasks. Standard models can perform degassing of liquids, and even be used as backing pumps for wide range turbomolecular pumps.