| Advantages | Disadvantages |

|---|---|

| Seal-less and oil-free | Low maximum speed |

| Self-priming up to 6 meters | Not very energy efficient |

| Simple cleaning/maintenance | Pulsed flow – requires dampener for reduction |

| Versatile design and function (can handle most media types) |

Are piston or diaphragm sprayers better? Piston pumps work best with lighter chemicals, such as herbicides and insecticides. Diaphragm – Diaphragm pumps don’t deliver as much pressure as piston, making them ideal for use in close application scenarios such as weed killing. But the diaphragm pump is more durable to chemical damage.

What is a piston pump sprayer? Piston sprayers include a cylinder housing in which, when pumping, a piston moves up and down to create pressure. Most piston models can reach up to 90 psi. Higher psi delivers smaller droplet size and has a further reach. Use with low abrasive, low viscosity spray liquids such as herbicides and insecticides.

What is difference between diaphragm and piston? Diaphragm-sensed regulators use a flexible element to adjust to these changes and to ensure constant outlet pressure and flow relative to depth; piston-sensed regulators use a sliding metallic piston that moves to adapt to these variations.

What is a diaphragm sprayer pump?

How does a diaphragm sprayer work? Diaphragm Sprayers: Diaphragm pumps feature a flat, diaphragm inside of housing held together by screws. When pumping, the diaphragm flexes up and down to create pressure. These pumps tend to be more durable because there is no contact with the cylinder wall. Diaphragm pumps can reach up to 60 psi.

What are the disadvantages of a diaphragm pump? – Related Questions

How does a piston diaphragm pump work?

Each piston is located in a separate oil chamber that equalizes the pressure of the oil behind the diaphragm to the media-side pressure. During the discharge stroke of the piston, the oil is compressed, causing the respective membrane to move outward and push the liquid out of the pump head.

How does a pump sprayer work?

How does back pack sprayer work?

How does a plunger pump work?

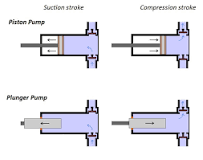

Rotary piston and plunger pumps use a crank mechanism to create a reciprocating motion along an axis, which then builds pressure in a cylinder or working barrel to force gas or fluid through the pump. The pressure in the chamber actuates the valves at both the suction and discharge points.

How does a piston regulator work?

When the regulator is pressurized by opening in the tank, the piston moves and allows air to past the high pressure seat. When the pressure inside the regulator reaches IP, then it closes, and air stops flowing. When you take a breath, it moves and lets air through.

What is a piston flush valve?

A piston flushometer features a molded cup with the upper and lower chambers separated by a rubber lip seal. This seal is extended inside a hollow piston, and the bypass hole can be found on the piston side wall. The relief valve seals the upper chamber from the lower chamber.

What is a diaphragm in a regulator?

What is a linear diaphragm pump?

Linear diaphragm pumps are equipped with linear magnetic and vibrating armature motor types. Linear pumps use electromagnetic force to move the piston or diaphragm up and down, and pump the air or liquid.

How long do diaphragm pumps last?

In general, diaphragms on metering pumps last about 6 to 12 months; gears on gear pumps last about 3 to 6 months; and motors usually last for years.

Can diaphragm pumps pump air?

Air-operated diaphragm pumps are positive displacement pumps that transfer liquids in wet commercial pumping applications. They run on compressed air and move slurries, solvents, and other high-viscosity liquids.

How much suction does a diaphragm pump have?

Normally, the suction lift of a diaphragm pump is limited to that corresponding to 14 feet of water at sea level. This amounts to a lift of approximately eight feet when pumping pulp containing 50% solids when the specific gravity of the dry solids is 2.65.

What does a piston pump do?

A piston pump is a type of positive displacement pump where the high-pressure seal reciprocates with the piston. Piston pumps can be used to move liquids or compress gases. They can operate over a wide range of pressures. High pressure operation can be achieved without adversely affecting flow rate.

What are the advantages of a diaphragm pump?

- HANDLES A WIDE VARIETY OF FLUIDS WITH HIGH SOLIDS CONTENT: …

- SELF PRIMING. …

- ABILITY TO RUN DRY. …

- EXPLOSION PROOF. …

- PUMPING EFFICIENCY REMAINS CONSTANT. …

- VARIABLE FLOW RATE AND DISCHARGE PRESSURE. …

- CAN NOT OVERHEAT. …

- NO MECHANICAL SEALS, COUPLINGS, OR MOTORS.

What are the types of sprayer?

- Boom sprayer.

- Boomless sprayer nozzle.

- Mist sprayer.

- Three-point hitch sprayer.

- Truck-bed sprayer.

- Towing-hitch sprayer.

- UTV sprayer.

- ATV sprayer.

What is a pressure sprayer?

A pressure sprayer is a chamber which is filled with a liquid which can be a lubricant, paint or chemical, then filled with compressed air to allow the liquid to be sprayed at pressure. Units are typically of cast iron or stainless steel design.

How much pressure should a pump sprayer have?

Pumping the handle or lever of your sprayer builds the pressure inside the sprayer tank. This pressure pushes the liquid out of the sprayer gun when the trigger is pulled. Most hand pump sprayers are limited to about 40 psi.

How far will a back pack sprayer spray?

A backpack sprayer can typically cover between 1000 and 10,000 square feet. The total area it can cover depends on the application rate of the product being sprayed as well as the volume of the sprayer tank.

How high can a backpack sprayer spray?

How far can a backpack sprayer spray? This depends on the pack, but most can handle between 10 and 30 feet, with an average of 20 feet.

What can a backpack sprayer be used for?

What is a backpack sprayer used for? The most common uses for backpack sprayers are for lawn care and pest control type applications. Backpack sprayers are used to apply fertilizers, herbicides, insecticides, fungicides and many more types of chemicals.

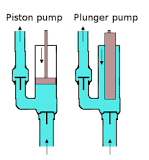

What is the difference between plunger and piston pump?

From an engineering standpoint, it’s easy to understand that the main difference between piston and plunger pumps is the placement of the seals or O-rings. Again, the plunger pump’s seal is stationary while the piston pump’s seal moves with the piston.

Is plunger pump Same with piston pump?

Plunger pumps and piston pumps operate in much the same way. They’re both reciprocating displacement pumps that pull water through a one-way intake valve, pressurize it and discharge it through a one-way outtake valve. Most pressure washer models have two (duplex) or three (triplex) pistons or plungers.

What is the advantage of the plunger pump over the piston pump?

| Advantages | Disadvantages |

|---|---|

| Wide pressure range – can achieve very high pressures | High operating and maintenance costs. |

How does back pack sprayer work?

What is a linear diaphragm pump?

Linear diaphragm pumps are equipped with linear magnetic and vibrating armature motor types. Linear pumps use electromagnetic force to move the piston or diaphragm up and down, and pump the air or liquid.